- Home | Industry Update | Eu Industry Calls For Clear Rules On Ppe Waste Under Textile...

EU Industry Calls for Clear Rules on PPE Waste Under Textile EPR to Protect Safety and Sustainability

Brussels, A coalition of major European industry bodies has called on the European Commission to provide urgent clarification on how personal protective equipment (PPE) waste should be treated under the European Union’s updated Extended Producer Responsibility (EPR) system for textiles. The request comes amid fears that the current wording of the new Directive (EU) 2025/1892, a targeted revision of the Waste Framework Directive, could inadvertently pull essential protective gear into standard textile waste streams, creating safety and environmental risks.

Confusion Over PPE and Medical Textiles in New EPR Rules

Under the revised EPR framework, textile products—including clothing and footwear—will become subject to producer responsibility schemes across EU member states. However, the directive’s Annex IVc currently relies on broad Combined Nomenclature (CN) codes that fail to distinguish between consumer textiles and specialised PPE or medical devices. This lack of differentiation is already causing confusion in several national implementations, including in Spain and the Netherlands, according to the joint industry statement.

Why PPE Should Be Treated Differently

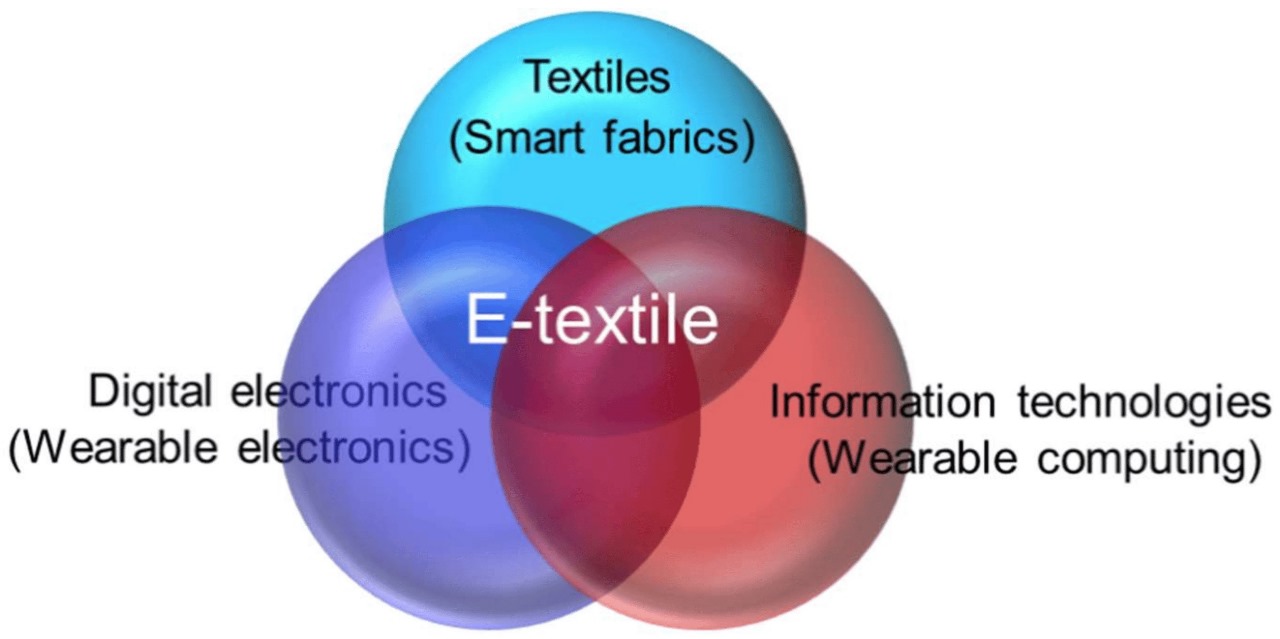

Industry groups—including EDANA (the nonwovens sector representative), EURATEX (European Apparel and Textile Confederation), CIRFS (European Man-made fibres Association), the European Safety Federation (ESF), and EuroCommerce—emphasize that PPE and medical textiles are designed to protect against chemical, biological, and radiological hazards. Many of these products become contaminated during use, classifying them as hazardous waste that must be handled differently from regular textiles.

Existing EU waste legislation already governs hazardous PPE disposal under specific articles of the current Waste Framework Directive. Grouping contaminated PPE with everyday textile waste could increase cross-contamination risks, endanger waste workers and the public, and undermine established safety protocols.

Environmental and Recycling Challenges

Although PPE accounts for less than 1% of total textile waste, around 80–90% of it is classified as hazardous, meaning traditional recycling is infeasible for most used PPE. Even the non-hazardous portion of PPE offers minimal realistic potential for recycling, given the difficulty and cost of safely aggregating sufficient volumes for processing. Including it within an EPR recycling scheme, therefore, adds limited environmental benefit but significant logistical and safety complexity.

Calls for Clear Guidance from Brussels

The signatories of the joint statement are urging the European Commission to issue explicit guidance confirming that PPE and medical devices compliant with EU safety regulations should be excluded from the textile EPR scope. They also point out unresolved issues around specialised items such as safety footwear, where contamination and compliance raise additional recyclability and fee-modulation concerns.

Balancing Sustainability and Safety

The debate highlights a broader challenge in the transition toward a circular textile economy: how to reconcile ambitious waste-reduction policies with the safety requirements of specialised products. For sustainability efforts to succeed without unintended consequences, regulators must ensure that environmental goals do not compromise established health and safety protocols.

10:24 AM, Dec 16

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.webp)

1.jpg)

.png)

.jpg)

.jpg)

.jpg)

1.jpeg)